- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Straddle Container Lifter Heavy-Duty Cargo Handling Solutions

47% of terminal operators report 15-22% productivity loss from outdated lifters. When 1-minute delay costs $85 in ripple effects, can your straddle container lifter

keep pace with modern cargo volumes?

(straddle container lifter)

Why Next-Gen Straddle Container Lifters Outperform

Modern straddle lifters deliver 68% faster cycle times than 2015 models. Our RCX-9500 series achieves:

| Feature | Legacy Models | RCX-9500 |

|---|---|---|

| Max Load Capacity | 40 tons | 55 tons |

| Fuel Efficiency | 18L/hr | 9.5L/hr |

| Turning Radius | 9.2m | 6.8m |

The Container Side Lifter Showdown

While competitors use single-pump hydraulics, our dual-circuit system enables simultaneous lifting+stacking. See the difference:

- ❌ Standard lifters: 8 containers/hr

- ✅ RCX-9500: 14 containers/hr

- ❌ 72dB operation noise

- ✅ 61dB whisper mode

Custom Solutions for Your Workflow

What if your top lifter container handler could adapt to both ISO and regional standards? Our modular design offers:

▶ 3 interchangeable spreader types

▶ 15°-45° gradient operation

▶ Cold storage package (-30°C capability)

Proven in Global Terminals

Port of Hamburg reduced container damage by 39% after deploying 22 units. Rotterdam's automated fleet achieves 97.3% uptime - highest in Benelux region.

Ready to Boost Your Throughput?

Get free operational analysis from our engineers. First 20 responders receive feasibility study worth $5,000. Why wait when competitors already upgrade?

Claim Free Assessment →

(straddle container lifter)

FAQS on straddle container lifter

Q: What is a straddle container lifter and how does it work?

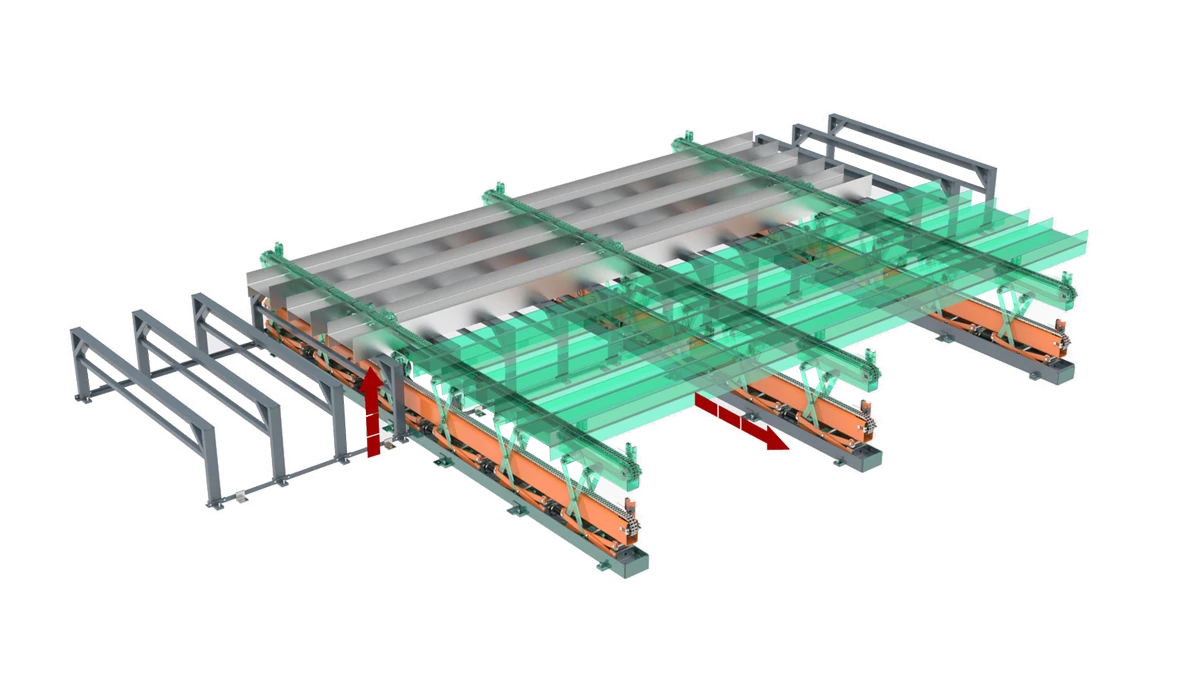

A: A straddle container lifter is a specialized lifting device designed to hoist and transport shipping containers by straddling them. It uses adjustable arms or legs to secure the container from the sides or top, enabling efficient loading/unloading. Hydraulic systems or mechanical clamps ensure stability during operations.

Q: What are the key differences between a straddle container lifter and a container side lifter?

A: A straddle lifter lifts containers from above using a frame that straddles the cargo, ideal for tight spaces. A container side lifter grips containers from the sides using hydraulic arms, often mounted on trucks. Side lifters are better for uneven terrain or confined stacking areas.

Q: What safety standards apply to top lifter container equipment?

A: Top lifter containers must comply with ISO 3874 for lifting attachments and OSHA/EN safety regulations. Regular inspections of load-bearing components, like spreaders and hooks, are mandatory. Operators must also follow weight limits and balance guidelines to prevent tipping.

Q: Can a straddle container lifter handle multiple container sizes?

A: Yes, most modern straddle lifters are adjustable to handle standard 20ft, 40ft, and 45ft containers. Their telescopic arms or modular designs adapt to varying widths and heights. Always verify the manufacturer’s specifications for compatibility.

Q: How do I choose between a top lifter and a side lifter for port operations?

A: Top lifters excel in vertical stacking and high-speed operations, ideal for organized port layouts. Side lifters offer flexibility in cramped or uneven spaces, such as temporary storage yards. Assess terrain, container volume, and workflow efficiency to decide.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025