- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

የካቲ . 16, 2025 11:04

Back To List

kran für den containerumschlag

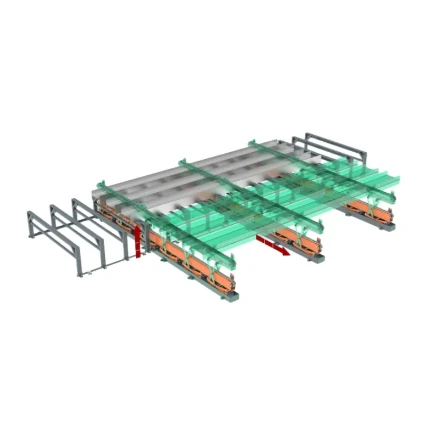

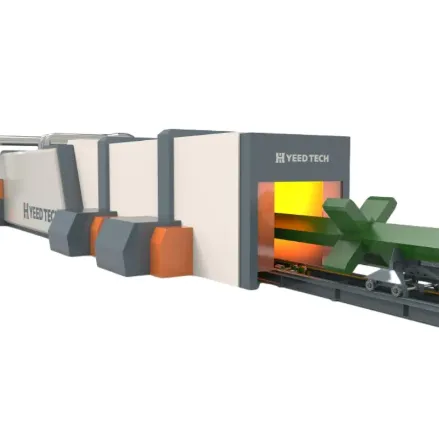

In the fast-evolving world of logistics and supply chain management, the crane for container handling has emerged as a cornerstone for operational efficiency and productivity. Whether you're supervising a bustling port or managing an inland logistics hub, the significance of these cranes cannot be overstated.

Moreover, the integration of advanced technologies like IoT and AI in modern cranes can drastically elevate efficiency. These technologies provide real-time data monitoring, predictive maintenance alerts, and remote operation capabilities, enhancing both safety and productivity. The cranes equipped with such smart technologies provide a competitive edge, especially in a landscape where minimizing downtime is key to maintaining profitability. Expertise in optimizing crane operations involves a deep understanding of the logistical challenges faced by different segments of the shipping and transport industry. For instance, customizing crane specifications based on factors such as container traffic volume, weather conditions, geographic location, and labor skill levels can yield significant improvements in operations. Lastly, experience plays a critical role in understanding the dynamic nature of global trade and its impact on container handling demands. The ability to adapt and align with these changes ensures that operations remain resilient and agile. Melding historical insights with contemporary trends allows businesses to predict potential challenges and devise robust strategies to address them, fortifying their market position. By encompassing the principles of EEAT, stakeholders in the container handling sector can make informed decisions that not only streamline their operations but also foster long-term growth and sustainability. As container volumes continue to surge globally, the relevance and indispensability of the right crane for container handling will only gain further momentum.

Moreover, the integration of advanced technologies like IoT and AI in modern cranes can drastically elevate efficiency. These technologies provide real-time data monitoring, predictive maintenance alerts, and remote operation capabilities, enhancing both safety and productivity. The cranes equipped with such smart technologies provide a competitive edge, especially in a landscape where minimizing downtime is key to maintaining profitability. Expertise in optimizing crane operations involves a deep understanding of the logistical challenges faced by different segments of the shipping and transport industry. For instance, customizing crane specifications based on factors such as container traffic volume, weather conditions, geographic location, and labor skill levels can yield significant improvements in operations. Lastly, experience plays a critical role in understanding the dynamic nature of global trade and its impact on container handling demands. The ability to adapt and align with these changes ensures that operations remain resilient and agile. Melding historical insights with contemporary trends allows businesses to predict potential challenges and devise robust strategies to address them, fortifying their market position. By encompassing the principles of EEAT, stakeholders in the container handling sector can make informed decisions that not only streamline their operations but also foster long-term growth and sustainability. As container volumes continue to surge globally, the relevance and indispensability of the right crane for container handling will only gain further momentum.

Prev:

Products Categories

Latest News

-

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025 -

Transforming Spaces with Diverse Steel Structures

NewsMay.28,2025 -

Steel Structural Elements: A Comprehensive Overview of Construction Solutions

NewsMay.28,2025 -

Optimizing Steel Structures: Paint Solutions, Assembly, and Design

NewsMay.28,2025 -

Fortifying Steel Structures with Intumescent Coatings and Design Excellence

NewsMay.28,2025 -

Enhancing Structural Integrity and Aesthetics with Specialized Construction Materials

NewsMay.28,2025 -

Unlock the Power of Modern Steel Structure Manufacturing with Advanced Equipment

NewsMay.27,2025