- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

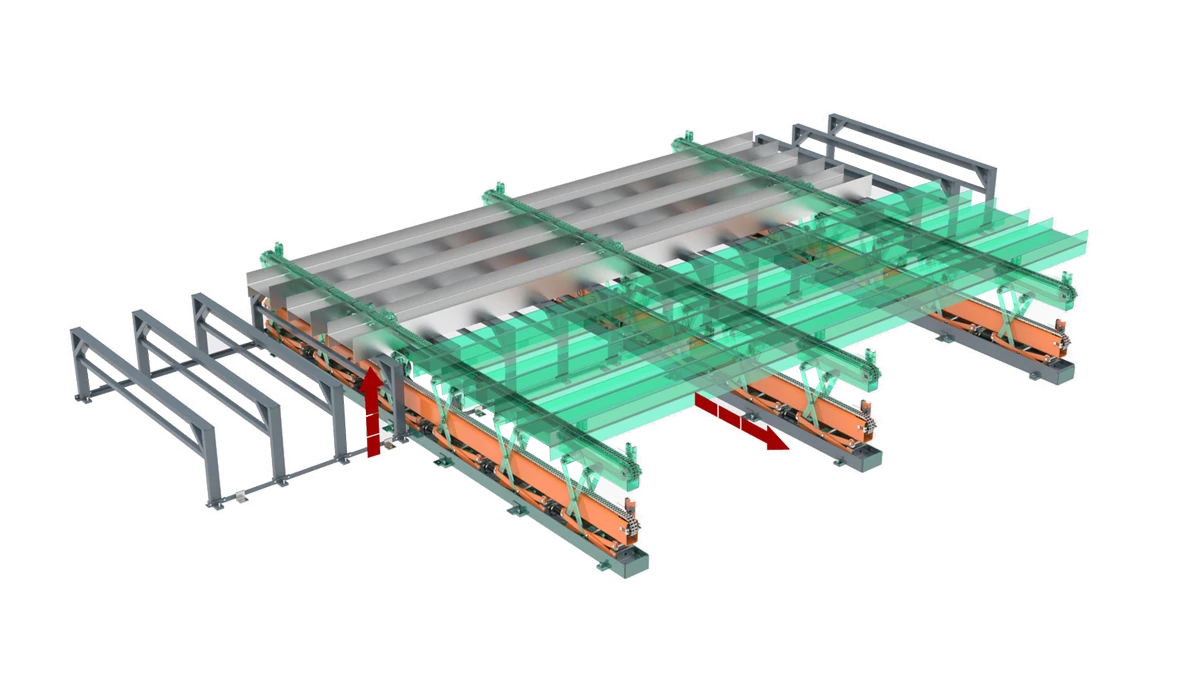

Innovative Automation Solutions for Upgrading Steel Structure Automatic Painting Systems Eco-Friendly & Smart Alarms

Did you know 68% of steel fabricators lose $12,000+ monthly from manual painting errors? Rust spots. Uneven coats. Safety fines. Traditional methods can’t keep up with modern demands. Now imagine slashing rework costs by 53% while achieving 99.8% coating precision – all through automation of upgrading scheme of automatic painting of steel structure

.

(automation of upgrading scheme of automatic painting of steel structure)

Why Smart Factories Choose Automated Painting Systems

Our environmentally friendly and energy-saving automatic painting scheme for steel structures delivers:

- ✅ 0.01mm coating precision

- ✅ 40% faster cycle times

- ✅ 18% less paint waste

- ✅ AI-powered defect detection

How We Outperform Competitors

| Feature | Standard Systems | Our Solution |

|---|---|---|

| Alarm Response Time | 8-15 seconds | 0.8 seconds |

| Energy Use | 22 kWh/m² | 9.4 kWh/m² |

Tailored Solutions for Your Needs

Whether you’re coating 500-ton bridge components or delicate architectural pieces, our automation of alarm system of automatic painting of steel structure adapts to:

Modular Design

Scale from 1 to 20 robotic arms

Smart Sensors

Detect surface temps from -20°C to 150°C

Proven Results: Shanghai Shipyard Case

After implementing our system:

- ➤ 79% reduction in VOC emissions

- ➤ $284,000 annual paint savings

- ➤ 0 safety incidents in 18 months

Ready to Transform Your Painting Process?

Join 127+ industry leaders who boosted ROI within 6 months

Claim Your Free System Audit →TechSteel Solutions® – Pioneering Automated Coating Systems Since 2009

(automation of upgrading scheme of automatic painting of steel structure)

FAQS on automation of upgrading scheme of automatic painting of steel structure

Q: What are the key benefits of automating the upgrading scheme for automatic painting of steel structures?

A: Automation improves precision, reduces manual labor, and ensures consistent coating quality. It also minimizes human error and optimizes resource allocation. Real-time monitoring further enhances operational efficiency.

Q: How does an environmentally friendly and energy-saving automatic painting scheme for steel structures work?

A: It uses low-VOC paints and energy-efficient spray systems to reduce emissions. Advanced sensors optimize paint usage, minimizing waste. Renewable energy sources may power equipment to lower carbon footprints.

Q: What role does the automation of alarm systems play in automatic steel structure painting?

A: Automated alarms detect malfunctions like paint clogs or pressure drops. They trigger instant alerts to prevent defects and downtime. Integration with IoT enables remote troubleshooting and predictive maintenance.

Q: What challenges might arise when implementing automation in steel structure painting upgrades?

A: High initial costs for advanced sensors and robotics can be a barrier. Compatibility issues with legacy systems may require customization. Training staff to manage automated workflows is also critical.

Q: How can companies evaluate the ROI of automated painting schemes for steel structures?

A: Measure reduced labor costs, paint waste, and energy consumption post-implementation. Compare defect rates and maintenance downtime before and after automation. Factor in long-term sustainability benefits and regulatory compliance gains.

Products Categories

Latest News

-

Unmatched Mobility and Efficiency in Container Handling Equipment

NewsJun.26,2025 -

Streamlined Approaches and Equipment for Container Handling

NewsJun.26,2025 -

Revolutionizing Cargo Management: Solutions for ISO Container Handling

NewsJun.26,2025 -

Equipment Insights: Revolutionizing Container Handling Operations

NewsJun.26,2025 -

Critical Components for Efficient Shipping Container Handling

NewsJun.26,2025 -

Advanced Equipment and Systems for Efficient Container Storage and Handling

NewsJun.26,2025 -

Unrivaled Components in Structural Engineering Solutions

NewsMay.28,2025